METSIM International LLC

The Premier Steady-State & Dynamic Process Simulator

The basis for analysis of all chemical and metallurgical processes is the mass and energy balance. Plant design, capital costs, and technical evaluations are all dependent on such calculations. METSIM is a general-purpose process simulation system designed to assist the engineer in performing mass and energy balances of complex processes. METSIM uses an assortment of computational methods to effect an optimum combination of complexity, user time, and computer resources usage.

METSIM originated as a metallurgical process simulation program, written to perform mass balances around the major unit operations of complex process flowsheets. Application of the program proved so successful that it was expanded to include detailed heat balances, chemistry, process controls, equipment sizing, cost estimation, and process analysis. The unique nature of the programming language, APL, allows modification and expansion of the system with minimum effort and permits the incorporation of continuing technological innovations in process simulation.

Many diverse processes have been modeled with METSIM, including:

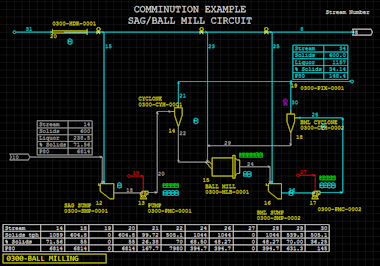

SAG/Ball Milling and Flotation of Various Ores

Chloride Leaching of Molybdenum Concentrates

Hydrochloric Acid Leaching of Alumina Clays

Gold Cyanidation / Precipitation

Roasting/Flash Smelting of Copper Concentrates

Acid and Carbonate Leaching of Uranium and Vanadium Ores

Heavy Media Coal Preparation Plants

Base Metal Smelting

Gold, Nickel, Uranium, and Copper Heap Leaching

Left: A traditional ball mill grinding circuit with hydrocyclones.

FEATURES METSIM

Complete Project Simulation in Five Modes:

- Mass Balancing based on Design Criteria

- Detailed Equipment Sizing and Equipment Lists

- Steady State Simulation: Mass & Energy Balancing

- Parameterization to Simulate Existing Plants

- Dynamic Simulation for Time-Varying Parameters

Flowsheeting Features:

- Easy to Add New Unit Operations

- Unlimited Number of Unit Operations & Streams

- Flowsheet and Dynamic Graphics

- May Calculate Portions of Flowsheets

- Robust Flowsheet Convergence

Chemistry Features:

- Extensive Thermodynamic Database

- Chemical Kinetics and Phase Equilibrium

- Eight Solid, Molten, Liquid, Aqueous, Gas Phases

Process Control Features:

- Feedback and PID Controllers

- Logic/Expert System Controllers

- Equations may be Entered by User

Budgeting:

- Mine Capital & Operating Costs

- Plant Operating Costs

Full Graphical Interface:

- Truly Interactive Program and Menus

- Easy to Learn, Get Immediate Results

Compatibility Features:

- Spreadsheet Interface to Excel

- DDE interface to Excel, InTouch

- XF interface to AutoCAD

Unit Operations:

There are presently over 200 unit operations available in METSIM, though many more may be simulated using a range of ‘generic unit operations’, including stream splitters, phase splitters, etc.

Some of the many unit operations in METSIM include:

Bins, Conveyors, Stockpiles

Autogenous, SAG, Rod and Ball Mills

CCD’s, Clarifiers, Filters, Thickeners

Mixers, Splitters, Distributors

Stoichiometric, Free Energy Reactors

CIP, CIL, Solvent Extraction

Flotation and Electrochemical Cells

Autoclaves, Boilers, Solar Ponds

Dryers, Kilns, Incinerators

Absorbers, Strippers, Cooling Towers

Dense Media Baths, Drums, Vessels

Gravity Jigs, Spirals and Tables

Breakers, Crushers, Impactors

Hydrocyclones, Screens, Classifiers

Ponds, Pumps, Sumps, Tanks

Equilibrium Stage Reactors

Evaporators, Crystallizers

Carbon and Ion Exchange Columns

Heap, Vat and Agitation Leaching

Converters, Furnaces, Roasters

Heat Exchangers, Flash Separators

Scrubbers, Baghouses, ESP’s

Dense Media Cyclones and Screens

Air Cyclones, Magnetic Separators

MODULES METSIM

- BASE/MASS BALANCE MODULE

This module performs mass balance calculations around each unit operation and includes Chemical, Mineral Beneficiation and Hydrometallurgical models. - HEAT BALANCE MODULE

This module performs heat balance calculations around each unit operation and reports temperatures and the heat contents for each stream. Heat losses and heats of reaction are also calculated and reported. It includes an extensive Thermodynamics Database and several Pyrometallurgical models. - COMMINUTION & GRAVITY SEPARATION MODULE

This module includes Crushing, Grinding, Classification, Plant Material Balances, Gravity Separation, Dense Media, Coal Preparation Washability and Liberation Models. - DYNAMIC SIMULATION & HEAP LEACHING MODULE

Dynamic simulation capability is being added to each unit operation as there is a demand for it; all operations concerned in heap leaching have already been provided with dynamic simulation. The heap leach module performs mass balances around the heap leach process including chemical reactions, precipitation and evaporation, solids and water inventories, and process controls. The model is non-steady state and generates time dependent plots of all critical variables in the operation. It includes DDE and PID Controllers, Heap Leaching, Solar Energy/Weather Module w/Solar Pond. Used to model processes that are time dependent. - CONTOURING MODULE

Used for building complex mine, stockpile, heap leach, and tailings models from DXF contour files and for displaying detailed data graphically. - MINE MODULE

The Mine Module allows import of drill-hole data, the mine block model and the mining sequence. The feed to the waste dumps, heaps, stockpiles and plant can then be taken directly from the mine. This allows dynamic simulation over the life of the mine. - METCOST, OPERATING COST MODULE

The Operating Cost Module is designed to enable the user to use the data generated by the flowsheet model to generate tables of operating costs. Costs are output in spreadsheet format and can be itemized by flowsheet section, unit operation, and cost types. A series of routines are provided in a menu structure for input, calculation, editing and output. Operating costs can be determined, at any time following the calculation of a model. - ENGINEERING MODULE

Sizes Equipment, Generates Equipment Lists, Adds Instrumentation, Generates Instrumentation Lists, Simulates Process Control System.

APPLICATIONS METSIM

METSIM is currently being used worldwide by hundreds of engineers to model a wide range of chemical and metallurgical processes:

- Copper, nickel, uranium, gold, and silver heap leaches

- Ferronickel kilns

- Incinerators for military wastes at a superfund site

- Electric furnace for EAF dust

- Selenium decontamination process

- Chloride process for titanium dioxide

- HCl process for high purity alumina

- Rare earth solvent extraction processes

- Large-scale potash solar ponds

- 100,000 ton per day grinding circuit

- Potash, soda ash and phosphate plants

- Dynamic model of lead refining

- Sulfuric acid plants

- Aggregate and gravel plants

- Copper, moly, lead, zinc concentrators

- HCl leach and magnesium electrolysis

- Zinc and gold pressure leach plants

- FeCl3 leach plants for molybdenum

- NH3 leach process for brass scrap

- Placer and CIP gold cyanidation plants

- Uranium acid/carbonate leach plants

- Outokumpu and INCO flash smelters

- Copper, lead, zinc, nickel smelters

- Precious metal and copper refineries

- Dense media coal preparation plants

- Nickel hydromet and smelting processes

- Magnesium and aluminum processes

- Direct iron ore reduction processes

- Beryllium and indium processes

Kata Kunci Terkait:

METSIM International LLC, jual software METSIM, harga METSIM, Metsim software engineers, metsim youtube